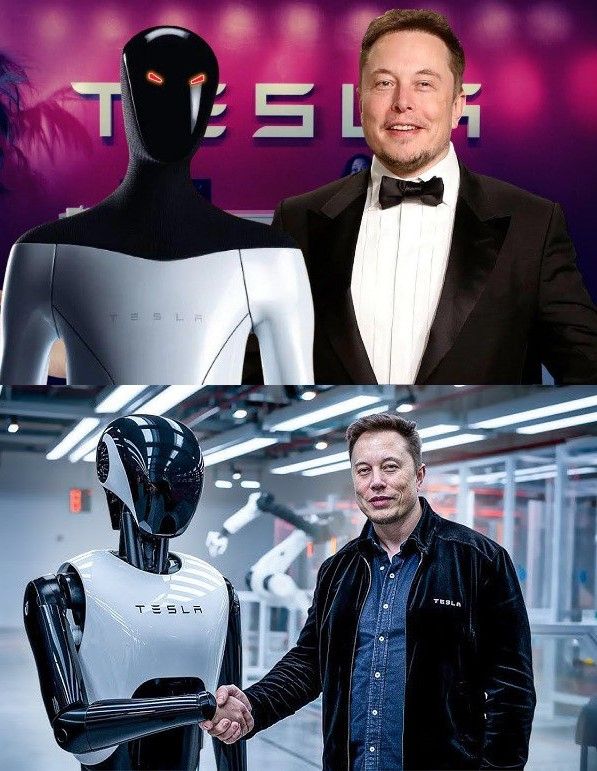

Tesla CEO Elon Musk has done it again, dropping a major hint about the future of robotics. In a recent announcement, Musk revealed that Tesla’s Bot Gen 3 Optimus humanoid robot is slated for mass production in 2025, with a staggering target price of $10,000 per unit. This development has electrified both tech enthusiasts and industry experts, sparking conversations about how Tesla plans to achieve such an ambitious goal.

The Optimus robot, first introduced as part of Tesla’s push into humanoid robotics, is designed to handle tasks that are dangerous, repetitive, or physically demanding. Musk has emphasized that the goal is not just to build a robot, but to create a workforce assistant capable of integrating into everyday life. While the prototype models have impressed audiences, the leap to mass production at such a low cost is unprecedented.

Early Production: Handcrafted Units at Giga Texas

As of now, Tesla has produced roughly 100 Optimus units, primarily at a small, handcrafted production facility within Giga Texas. These early models are assembled by hand, showcasing the intricate engineering required for humanoid robotics. Elon Musk himself has acknowledged the complexity of the project, stating on X (formerly Twitter):

“Complexity per unit mass is much higher with humanoid robots, but still I think it ends up costing less than half of a car.”

This admission highlights the enormous challenge Tesla faces: humanoid robots are inherently more complex than vehicles in terms of motion, artificial intelligence, and sensory integration. From advanced motors to precision sensors and AI-powered decision-making, every unit represents a remarkable technological feat.

How Tesla Plans to Scale

The real question on everyone’s mind is: how will Tesla scale production to thousands of units per year? Musk has confirmed that 2025 will see the production of thousands of Optimus units for internal testing and training, ahead of a public launch expected at the end of 2025 or early 2026. This approach allows Tesla to refine assembly processes, improve AI training, and ensure the robots meet performance standards before mass release.

Unlike cars, robots require integration of multiple fields of science and engineering, from mechanical and electrical systems to machine learning and advanced sensors. Tesla’s approach appears to focus on automation in assembly, where many units can be produced efficiently once initial prototypes and processes are perfected. Musk’s claim that each robot could cost less than half a car reflects Tesla’s confidence in streamlining production at scale.

Challenges and Opportunities

Historically, Tesla has faced significant production hurdles. From the Model 3 “production hell” to the Cybertruck and Semi, Musk has repeatedly pushed the limits of manufacturing while overcoming obstacles. Optimus, a humanoid robot, represents a new frontier — arguably more complex per unit mass than a car — but Tesla is applying lessons learned from its automotive production lines.

Experts speculate that the success of mass-producing Optimus depends on several factors: automating precision assembly, reducing material costs, refining AI integration, and ensuring robust testing. Given Tesla’s reputation for innovation and Musk’s ambitious timelines, the company may indeed achieve what no other robotics firm has: affordable humanoid robots at scale.

Implications for Industry and Society

If Tesla succeeds, the Bot Gen 3 Optimus could transform industries ranging from manufacturing and logistics to healthcare and home assistance. Robots could handle repetitive or dangerous tasks, reduce labor shortages, and create a new wave of productivity. For consumers, a $10,000 humanoid robot opens possibilities that were previously unimaginable, from home assistance to personal robotics.

Moreover, mass production of Optimus represents a milestone in AI integration with physical robotics, potentially making humanoid robots a common part of daily life. Tesla’s move could accelerate the adoption of robotics globally, reshaping workforce dynamics and inspiring competitors to innovate at unprecedented speed.

The Road Ahead

As Tesla prepares for the first large-scale rollout of the Optimus Bot Gen 3 in 2025, the tech world watches with anticipation. The combination of affordable pricing, advanced AI, and robotic engineering makes this one of the most ambitious projects in recent history. While challenges remain, Musk’s vision is clear: to make humanoid robots accessible, practical, and integrated into modern life, potentially revolutionizing the way we live and work.

In a few short years, what began as a futuristic concept may become a tangible reality, as Tesla continues to push the boundaries of robotics and artificial intelligence. The $10,000 Optimus is more than a robot — it’s a glimpse into a future where advanced technology is affordable, scalable, and transformative.

News

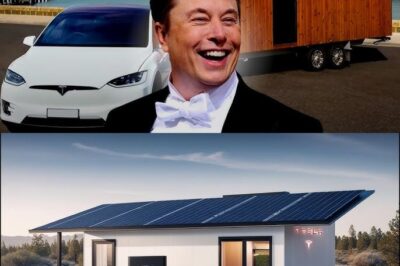

ELON MUSK’S $19,999 TESLA TINY HOUSE — LUXURY, TECH, AND SUSTAINABILITY IN ONE COMPACT PACKAGE

Elon Musk, the billionaire entrepreneur famous for SpaceX, Tesla, and groundbreaking technological innovations, has once again pushed the boundaries —…

ELON MUSK’S SON STEALS THE SHOW — X Æ A-Xii’s Adorable Viral Moment Melts the Internet

In a world dominated by Elon Musk’s high-profile ventures — launching rockets into space, steering Tesla’s electric empire, or sparking…

ELON MUSK’S PRIVATE JET FORCES EMERGENCY LANDING — THE BIZARRE INCIDENT NO ONE SAW COMING

Elon Musk, the billionaire entrepreneur known for rockets, electric cars, and bold visions of artificial intelligence, has always thrived on…

“ELON MUSK’S $35 MILLION TEXAS ESTATE REVEALS A SIDE OF HIM WE NEVER KNEW” — Designed for His 11 Children, the Property Shows the Billionaire as a Father, Not Just a Tech Icon

Elon Musk, the billionaire entrepreneur known for SpaceX, Tesla, Neuralink, and ambitious visions of colonizing Mars, has once again captured…

“APPLE IS NOT MY COMPETITOR ANYMORE” — Elon Musk Unveils Tesla Pi Phone, Ignites Fiery Response From Tim Cook and the Tech World

Elon Musk has once again captured global attention — this time not with a rocket launch or an electric vehicle,…

“A LIFE CUT SHORT ON K’GARI” — Piper James, Canadian Teenager, Confirmed De-ad on Queensland Island

A teenager found dead and surrounded by dingoes on a Queensland tourist island has been named as 19-year-old tourist Piper…

End of content

No more pages to load